The TRILAB AzteQ Industrial is an FDM 3D printer featuring a tall-format build chamber and delta kinematics, ensuring industrial-grade fast and accurate printing. Since 2021, TRILAB professional delta 3D printers are a part of the Prusa Research company.

One of the most distinctive features of the machine is its enclosed build chamber that is actively heated up to 80 °C. In combination with the heated print bed, this ensures excellent printing results with all consumer-grade and a lot of engineering materials, including fiber-filled composites.

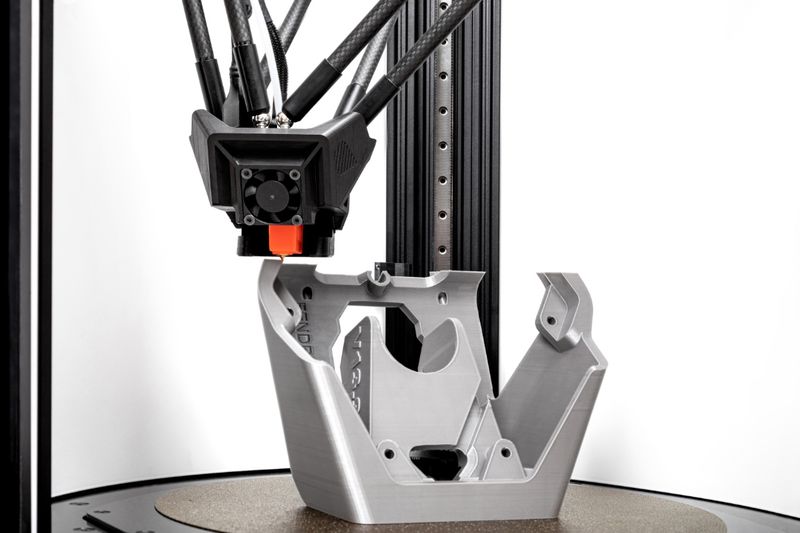

The printer is equipped with a magnetic swappable print head with an E3D Volcano hotend, which can be easily replaced with an E6 or SuperVolcano, depending on project requirements. The default 0.4 mm brass nozzle can be changed for other type and diameter nozzles as well.

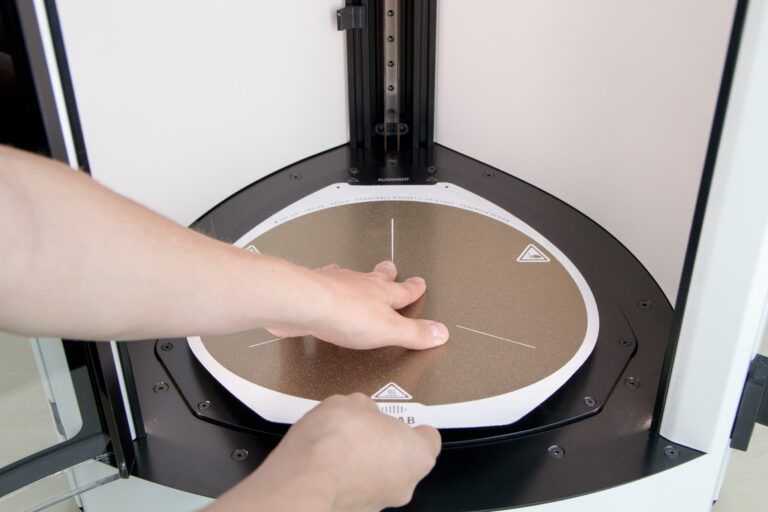

Due to the magnetic print bed with TRILAB interchangeable flexible PrintPads, the user can select the best suitable surface for the filament being printed and ensure perfect first layer adhesion and easy print removal.

Due to the thermally insulated build chamber, the heat loss is minimized and the printer surface does not get hot during printing. To protect the machine’s electronics from overheating, they are placed in a separate compartment with active cooling to ensure stable operation and longer lifespan.

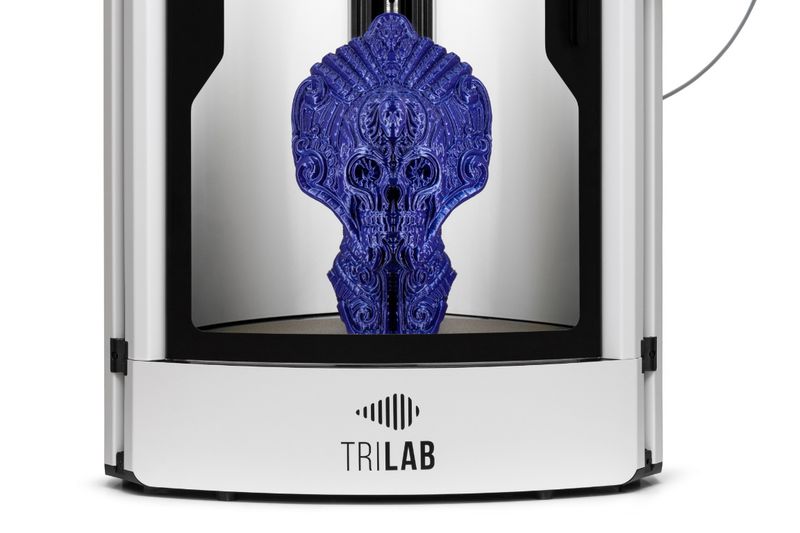

The machine can print layers with a minimum height of 50 microns. Delta kinematics ensures high accuracy and repeatability of printing results, allowing for detailed models with excellent surface finish.

The TRILAB AzteQ Industrial can print with a wide range of thermoplastics including ABS, ASA, PA, PC, PP, PETG, CPE, PLA, TPU, as well as carbon fiber composites, and others. Due to the actively heated enclosed build chamber and heated print bed, temperature-sensitive materials can be reliably printed without warping and deformation. The swappable print heads and flexible PrintPads with various surface textures allow the user to choose the optimal printing conditions for each type of filament, ensuring the best result.

The build volume of the TRILAB AzteQ Industrial measures 300 mm in diameter and has a height of 400 mm. This allows using the printer for prototyping or end-use part production in different industries, including but not limited to automotive, chemical, machinery, architecture, and more.

The printer is operated using the wireless 6.5" DeltaControl display, which is actually a smartphone with the DeltaControl app installed.

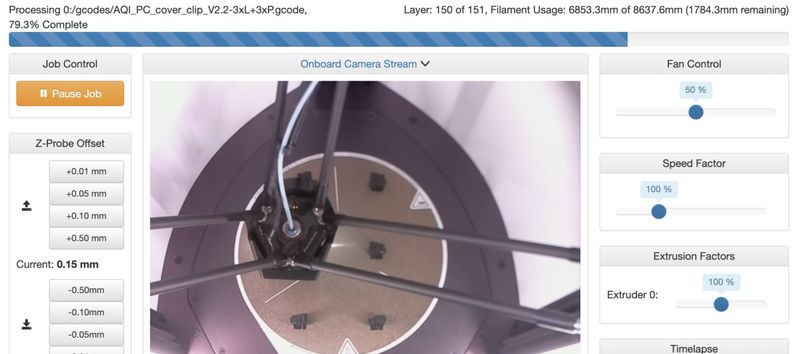

You can also manage the AzteQ via a web interface from PC or Mac. The user can operate the printer remotely and monitor the printing process due to the built-in camera. It is possible to operate multiple printers from a single computer.

The recommended software is PrusaSlicer with an advanced set of tools and pre-defined profiles for 250+ materials.

For some items, package content may change. In case of any questions, please get in touch.

The TRILAB AzteQ Industrial 3D printer is available in a white-and-black color scheme with a transparent door. Its elegant look makes it ideal for any industrial application.

The machine dimensions are 23.2 x 20.5 x 41.3 in (590 x 520 x 1050 mm). It weighs approximately 83.8 lb (38 kg).

To learn the current price of the TRILAB AzteQ Industrial 3D printer, click the "request the quote" button and fill in the form. We will contact you as soon as possible and send you all the details.

Update your browser to view this website correctly. Update my browser now